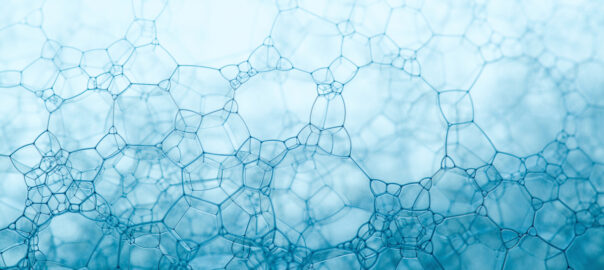

The University of Melbourne has been sponsored by AMIRA Global, Newcrest Mining and Newmont to develop an open pit mine design based on the physical properties of soap bubbles.

The atypical ‘Bubble Pit’ approach used an algorithm to develop a software which solves operational issues found in traditional mine designs.

“For decades, the industry has been trying to find a way of incorporating geometrical constraints of the shapes of the pits into the design process, in order to maximise value and satisfy operational needs,” the university stated.

Using the software, from technology start-up Thinking Mine Design, miners can now design pits in nested clusters that provide connectivity and minimum bench width to allow equipment access.

“The changes to the way open-cut mines are designed have the potential to support values of between five and 15 per cent greater than previous pit construction allowed, depending on the complexity of the design,” the university stated.

Newcrest and Newmont are now trialling the technology in their operations, after the software was developed thanks to a grant from AMIRA Global.

“The team is now looking at two additional software phases exploring how the bubble model can address scheduling and haulage,” the university stated.

“Newmont and Newcrest have agreed to sponsor the further development based on the success of the Bubble Pit software.”

The research was led by mathematician professor Joachim Rubinstein from the University of Melbourne’s School of Mathematics and Statistics and mining engineer Juan L. Yarmuch from the University of Chile.

Both experts have been involved in a number of projects to develop and optimise mine designs and mining processes, such as Yarmuch’s work in ramp designs and open pit crusher system locations.